Basic principles

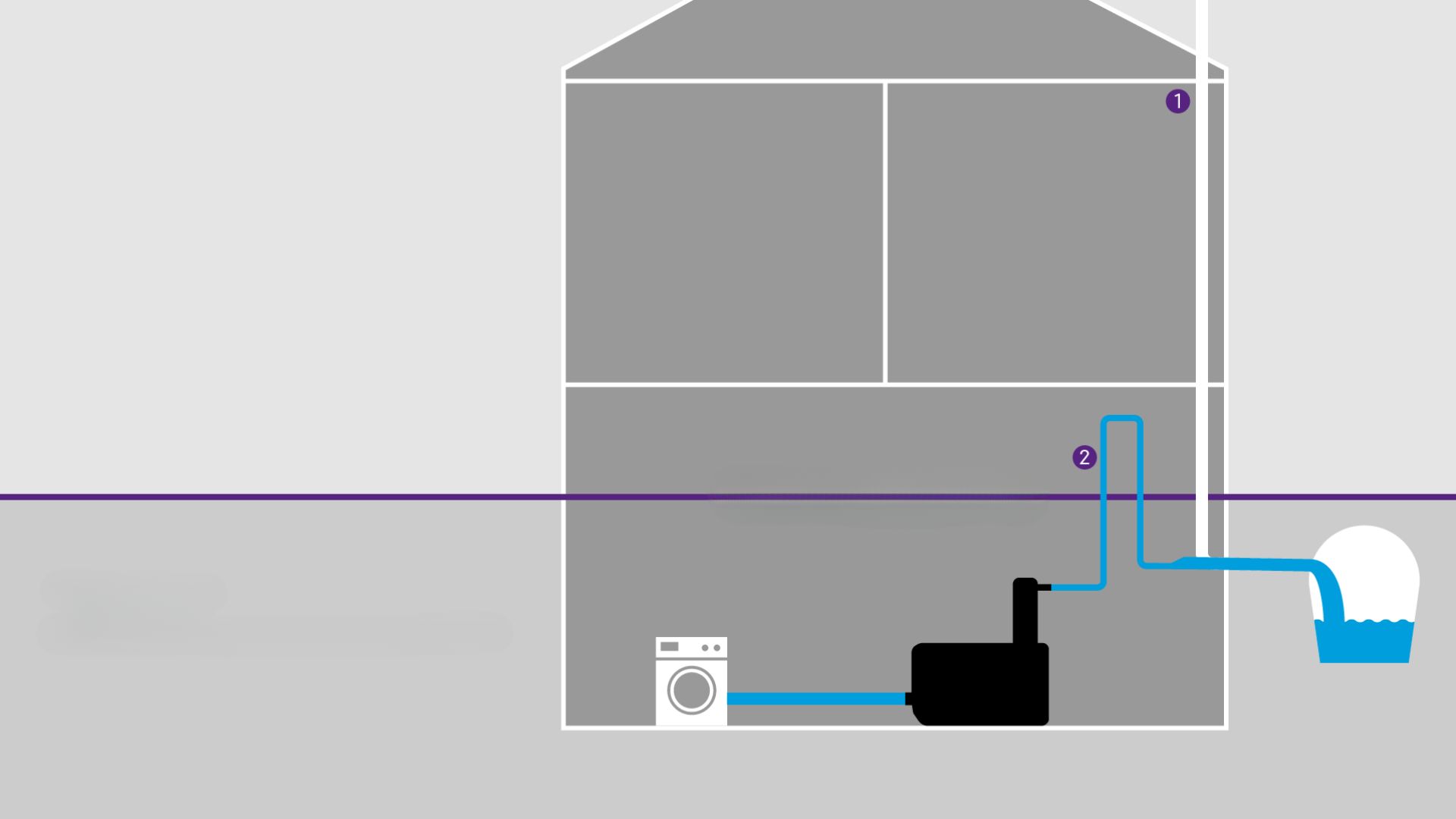

Lifting and pumping stations pump off wastewater via a pressure pipe. The pressure pipe runs with the base of the backwater loop above the backwater level and thus prevents the penetration of water from the sewer. To guarantee problem-free operation, the pressure pipe is ideally designed such that its contents are completely discharged with each pumping process.

Standard specifications for the pressure pipe

Pressure pipes are connected to vented basic or collecting pipes. Connections to additional drainage objects or ventilation valves as well as discharges into wastewater downpipes are not permitted. Effective energy conversion must be ensured if the pressure pipe leads into a chamber. This can be achieved, for example, by designing the chamber as a pressure relief chamber. Further specifications for pressure pipes result from the type of system.

Caution: check peak loads!

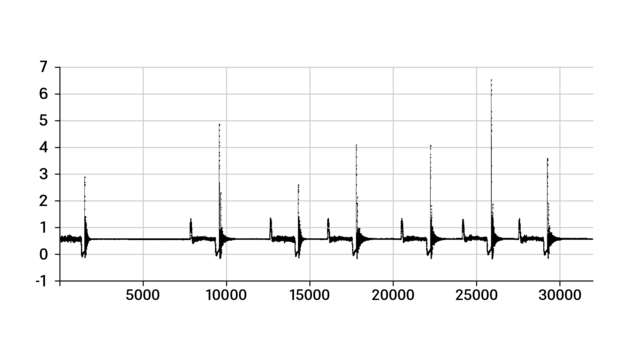

According to the standard DIN 12056-4, the pressure pipe must withstand at least 1.5-times the maximum pump pressure. Nevertheless, the forces acting on the pipe should be checked carefully, as other factors may require an even more resilient pipe material. Some of these factors include:

- Pressure shocks

- Soil loads

- Temperature influences

- Test and rinsing pressures

- Long-term behaviour and warranty periods

PE-HD

- Rods or rolls

- Underground or above ground installation

- Various

- Virtually all nominal sizes

- Standard basis: DIN 8074 & 8075

PVC (PVC-U/PVC-C)

- Stangenwaren

- Einbau ins Erdreich oder frei verlegt

- Druckstufen: PN10, PN16

- Nahezu alle Nennweiten

- Normgrundlage: DIN 8061 & 8062

SML / KML / TML

- Stangenware

- Einbau ins Erdreich (TML) oder frei verlegt (SML / KML)

- Nur mit Schellen & Krallen druckbeständig

- Gängige Nennweiten: DN 50+

Flexible pressure pipe for underfloor lifting stations

Flexible pressure pipes are an ideal solution when installing lifting stations in the floor slab. They are used to connect the pressure pipe connection of the lifting station to the pressure pipe on site. We can offer the KESSEL pressure pipe set, a flexible PVC pressure hose with reinforcing spirals (nominal size DN 32 or DN 40) including an adapter fitting for connection to the lifting station.