Selection criteria for polymer and metal drains

When planning drain technology, it is important to check which material is most suitable for the type(s) of wastewater and the climatic conditions. The substances and concentrations thereof contained in the wastewater, the wastewater, floor/ground and air temperature and the weather conditions must be taken into consideration. Here you can find out what loads the drain technology materials have to withstand, the advantages and disadvantages of drains made of different materials and choose a suitable material for your application using our List of resistances.

General requirements for drainage materials

All materials used for the production of drain technology must either be inherently corrosion-resistant or have corrosion protection applied to it. In addition, they must always be able to withstand domestic wastewater at temperatures up to 95 °C. Materials exposed to industrial wastewater are subject to the relevant planning specifications.

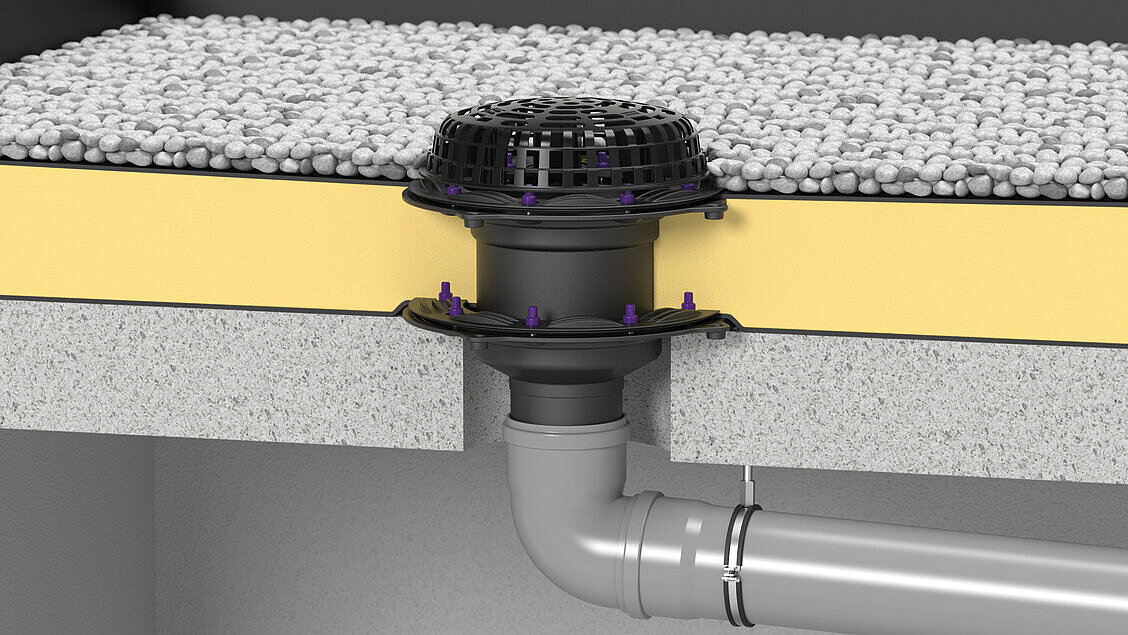

Special case for roof drains

As roof drains are exposed to weather all year round, special requirements apply to their materials: they have to withstand rainwater and UV radiation as well as outdoor temperatures ranging from -20 to 80 °C – or up to 220 (±5) °C when the drain is installed on a bitumen-coated roof.

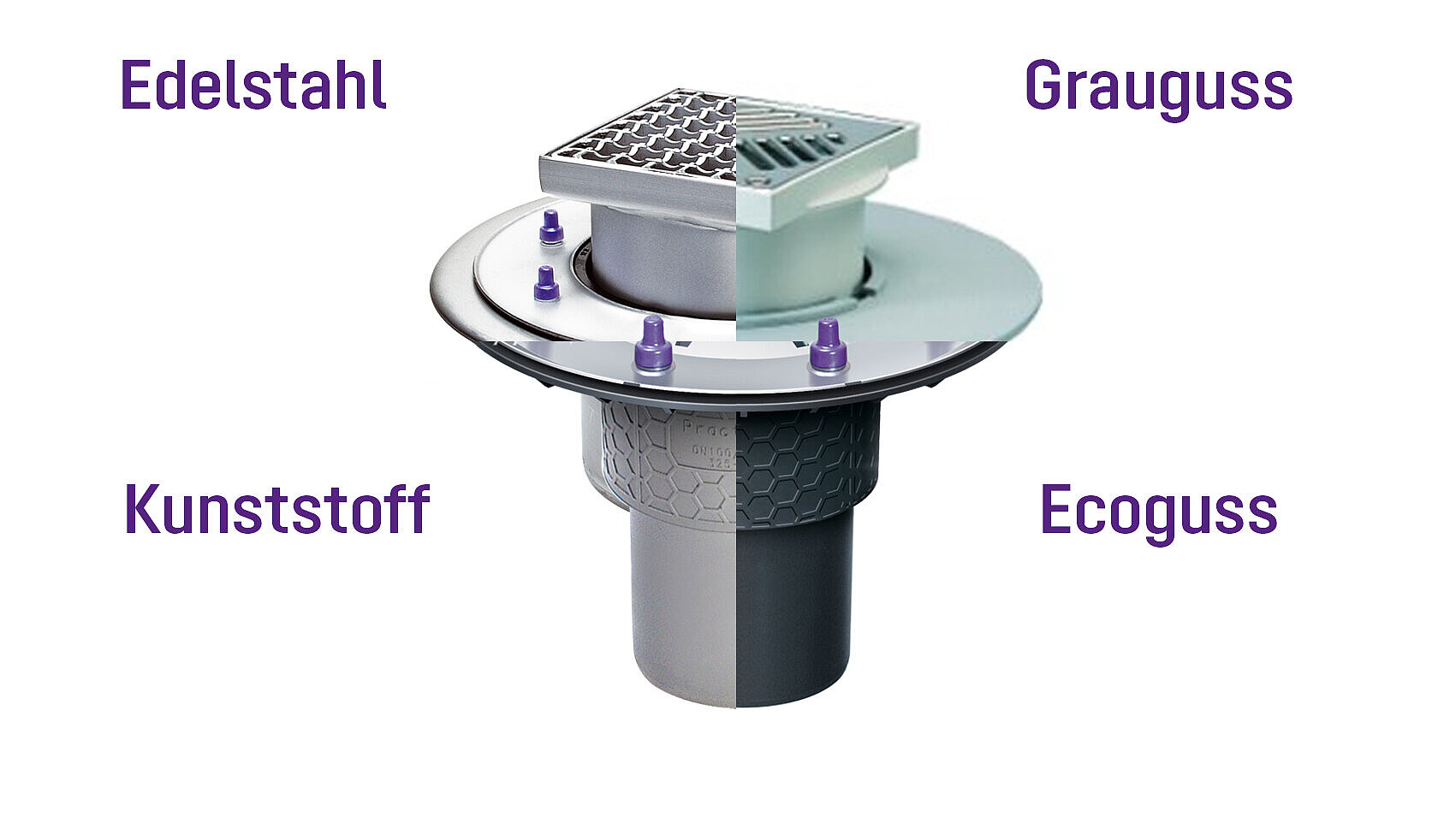

Polymer (e.g. PE-HD, PP, PVC)

Easy to install and resistant to a lot of different aggressive wastewater. Good "all-rounder" for normal applications, such as domestic drainage in private homes and hotels. Requires no earthing or corrosion protection.

Stainless steel (e.g. 304, 316)

Extremely hygienic and therefore a good choice for intensively used places contaminated with bacteria and/or germs, such as breweries, commercial kitchens, hospitals or swimming pools. Requires earthing and corrosion protection.

Grey iron

Suitable for extremely hot environments such as bitumen-coated roofs due to its heat/fire resistance. Corrosion protection and, if necessary, earthing requirements as well as restricted hygiene.

The best of three worlds: Ecoguss composite material

In addition to conventional materials, such as grey iron, stainless steel and polymer, a fourth alternative is now available: Ecoguss, a high-tech composite material with polymer and metal components developed by KESSEL, combines the advantages of all conventional materials. It therefore requires no earthing, is corrosion-free, heat and acid resistant and is very hygienic thanks to its smooth surface. The individual properties can also be selectively strengthened by adjusting the mixing ratio of the ingredients. This means that drains made of Ecoguss can be safely installed virtually anywhere and more easily than stainless steel and grey iron drains thanks to their relatively low weight.

Selection of materials with the KESSEL resistance list

You can use our resistance list to check which material will best withstand the wastewater arising in your application. There you will find a list of the most common types of wastewater with assessments of the different materials with respect to their resistance.