- Tiles and joints incl. tile adhesive

- Joint sealing according to DIN 18534-1

- Cement floor

- Separating layer

- Insulation

- Waterproofing foil / separating layer ≥ 1.5 mm according to DIN 18534-2

- Concrete

- In the case of a penetration / floor structure, observe fire protection if necessary

- Capillary-tight grouting with reactive resin

- Joint sealant with closed-cell rope caulk

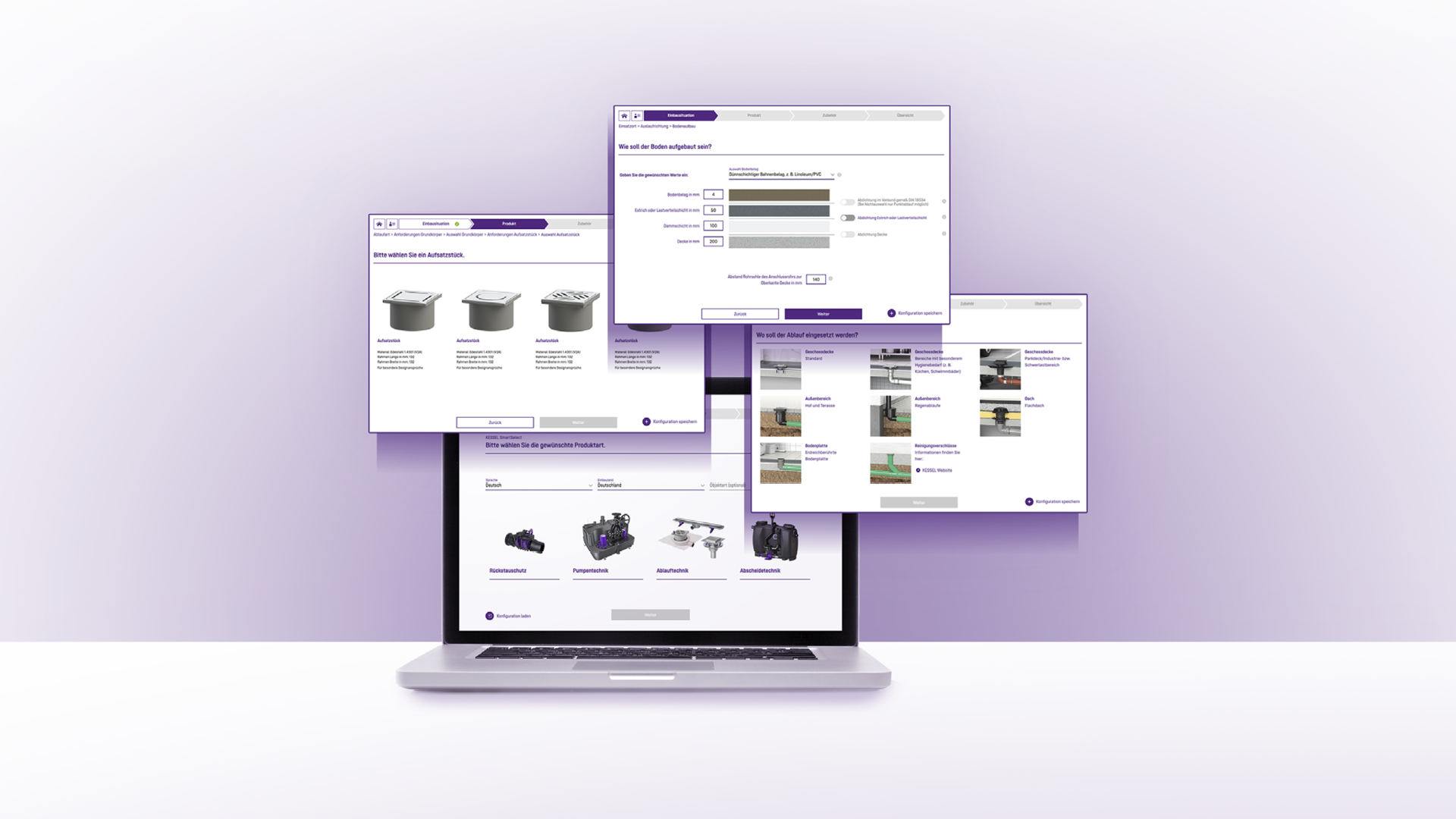

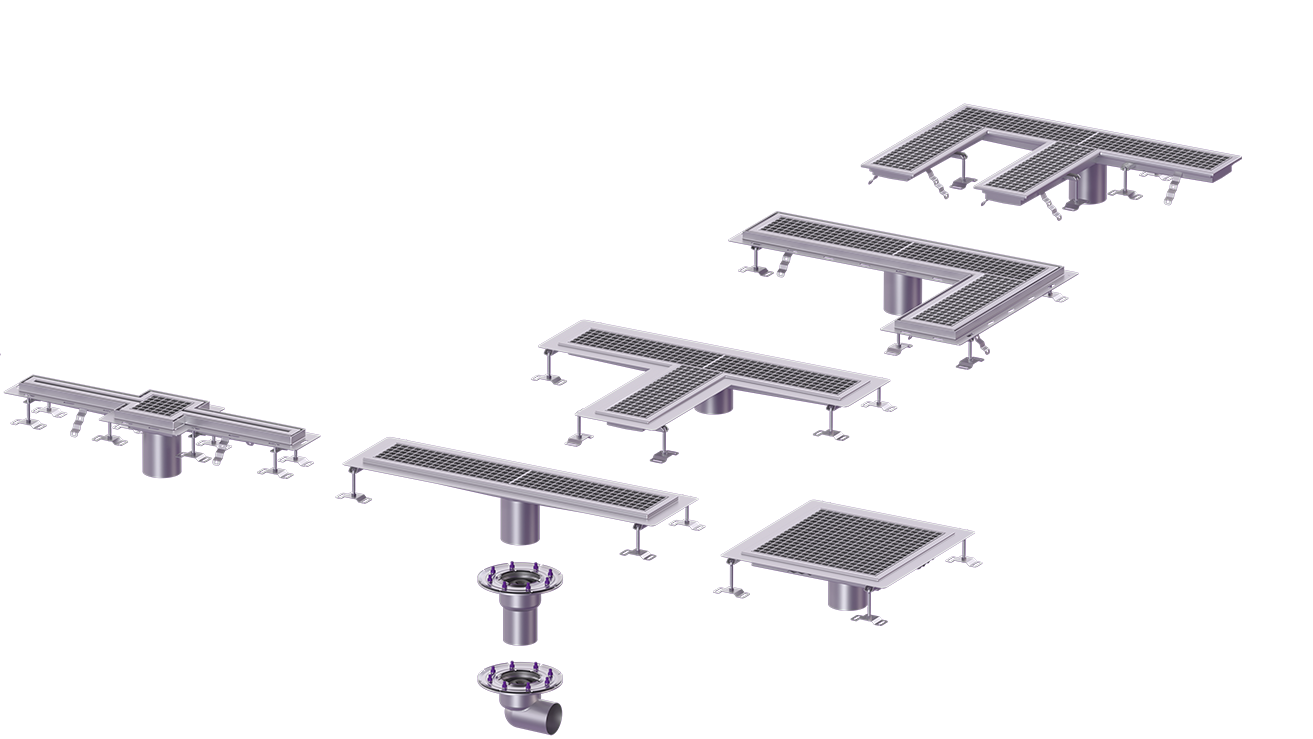

Due to the separating layers (4/6) or waterproofing layers (6), it is often not possible to fix stainless steel channels during the installation until the complete grouting of the channel and integration into the floor structure has been carried out.

The KESSEL mounting brackets provide a simple and practical solution in this case.

The mounting brackets are fixed securely to the existing screed. The mounting brackets and transport bars of the channel are connected using threaded rods and aligned to the desired height level. After grouting, the transport bars and mounting brackets can be removed again, ensuring the precise positioning of the stainless steel components without damaging the lower separating layers and waterproofing layers.

The maximum channel width for using KESSEL mounting brackets is 1,000 mm.

The KESSEL mounting brackets are a reusable installation aid. This means that after the installation and grouting of the stainless steel channels, the mounting brackets are removed and returned to KESSEL. Missing or damaged mounting brackets will be invoiced to the customer.

Quality "made in Germany"

The entire Ferrofix product range is developed and manufactured in Germany in our own competence centre in Ulm. With more than 40 years of experience as a system provider for stainless steel products in the drainage sector, the team of experts at KESSEL Inox therewith provides you with a reliable all-round service through to sophisticated individual solutions.